SMART MONITORING FOR INFORMED DECISIONS

Smarter Industrial IoT for Any Compressor, Any Industry.

Proactive Maintenance

Proactive maintenance means fewer surprises.

Stay ahead of equipment failures with real-time condition monitoring and predictive analytics. Atlas IQ continuously tracks operational health and flags abnormalities before they become critical - allowing your team to act before downtime occurs.

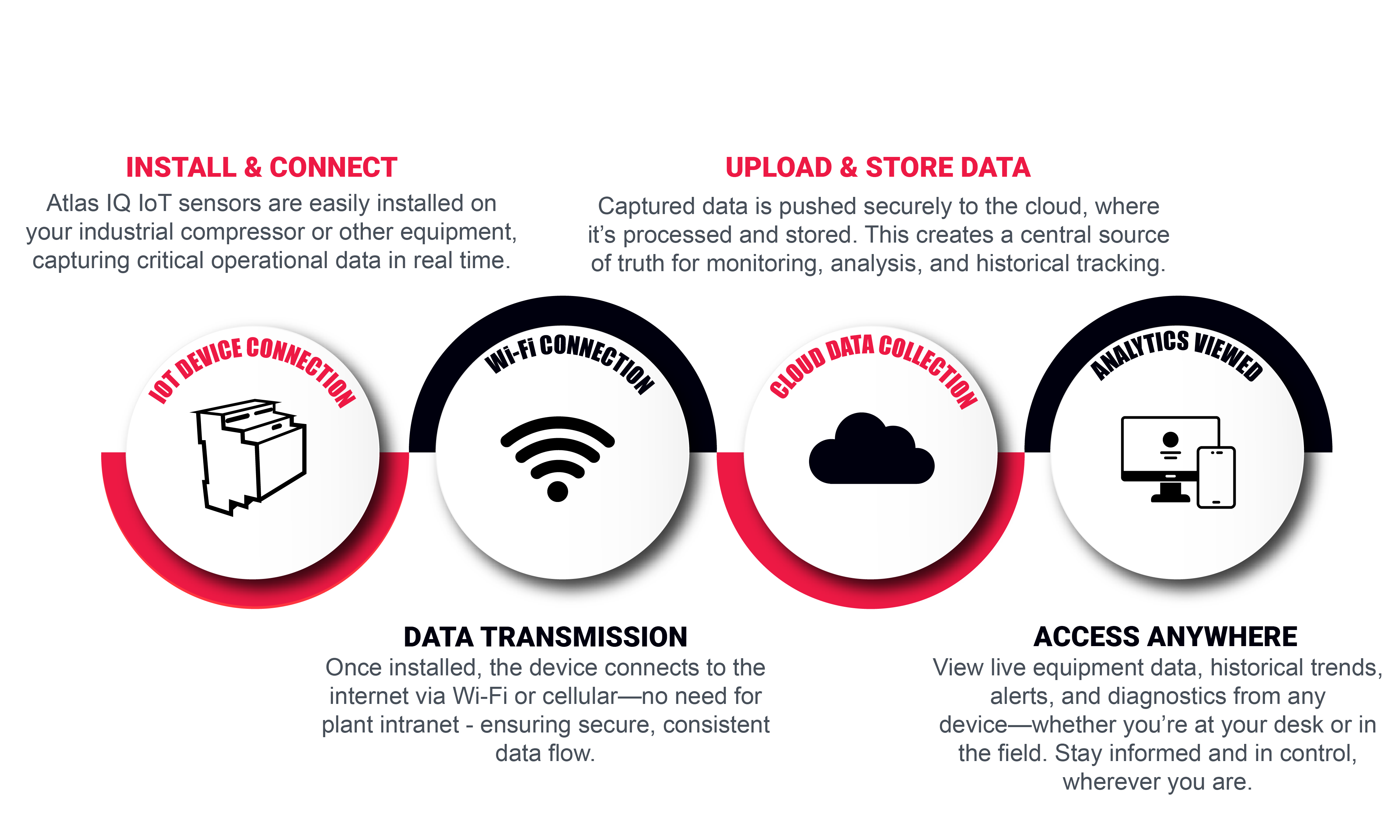

Atlas IQ provides real-time condition monitoring and alerts to help service teams stay ahead of failure before it happens.

With automated alerts and historical trend analysis, technicians know what’s wrong before they arrive on site, reducing guesswork, improving response times, and increasing first-time fix rates. This smarter, data-driven approach helps extend equipment life, lowers repair costs, and boosts overall operational efficiency.

Track Equipment Insights

The mobile app puts live equipment data directly in your hands - whether you're on-site or remote. With intuitive dashboards and real-time alerts, you can instantly see how your systems are performing, track anomalies, and identify inefficiencies before they become costly issues.

.png)

-01.png)